Hey! Raymond here. I’m a product design engineer.

Chargepoint MDE. University of Illinois Urbana-Champaign Engineering student. Expected graduation: December 2027. Portfolio version 10-09-2025.Raymond Ka Tsui

Mechanical Design Engineer, Intern @ ChargePoint

Mechanical Engineer, Intern @ Yummy Future YC-19

Systems Engineering & Design @ UIUC.

Contact me:

(510) 399[DASH]9807

rayktsui[AT]gmail[DOT]com

Formerly,

Hardware Engineer, Temp @ Eikon Therapeutics

Mechanical Engineer, Intern @ Eikon Therapeutics

RF Validation & Test, Intern @ UL Solutions

At a Glance

Looking / open for:

Mechanical, Product Design, TPM, PM

Internship roles - Spring/Summer 2026

8 years of experience in 3D CAD:

Emphasis on startup rapid prototyping

“move fast, break fast”.

NX, Solidworks, Onshape, Creo, CATIA

Certified Associate @ Onshape (ID: 8cyg)

The Projects.

The skillsets.

What’s with all of the portfolio robots?

I grew up in a robotics heavy environment.

However — I did not have the available resources to really financially support the building of multiple FTC competition robots. As a result, I spent most of my free time stuck to CAD, where I can truly express my engineering skills without financial constraints.

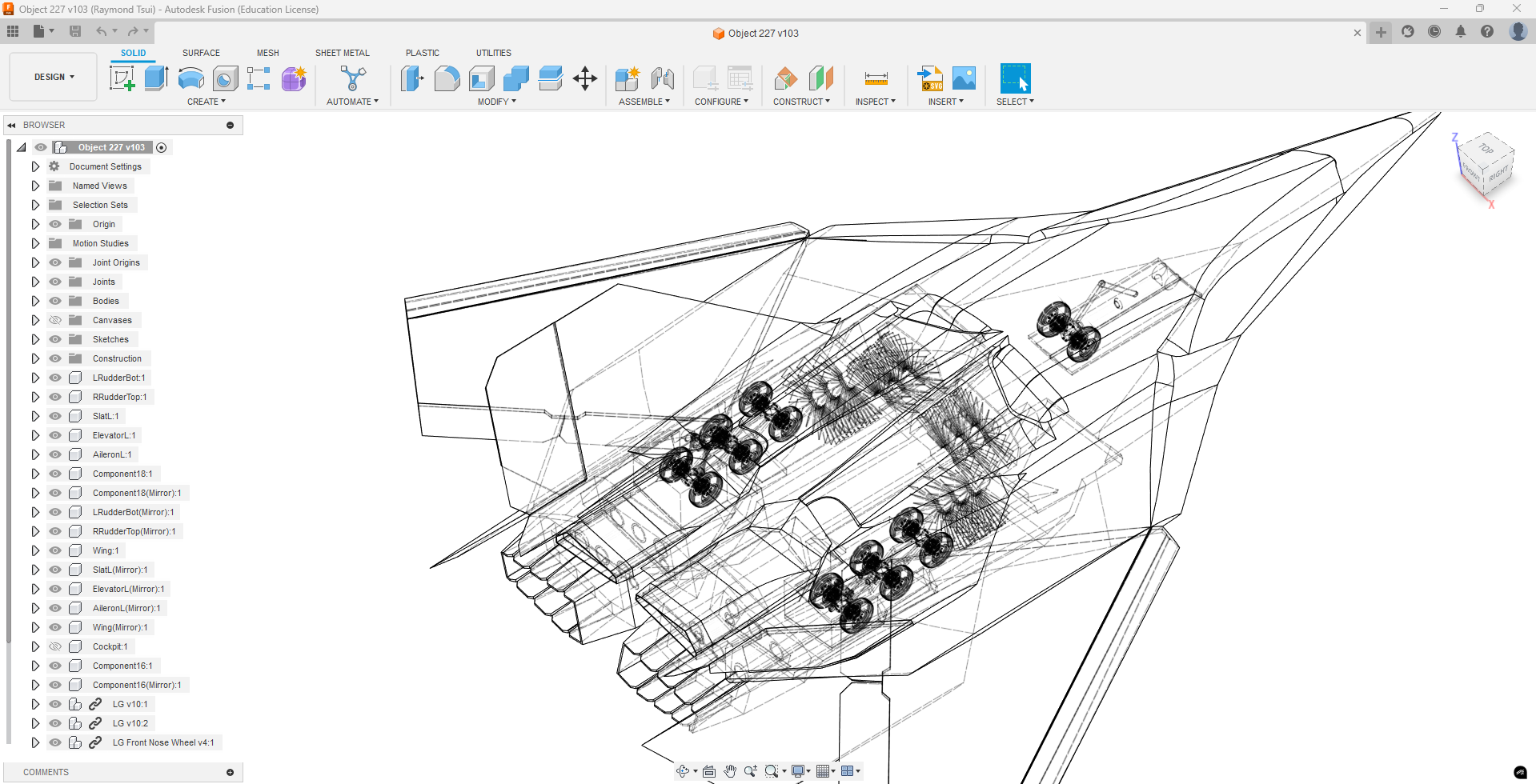

One of my hobbies that I like to do whenever I’m not engaged in some sort of engineering project is graphic design and 3D digital art. As a result, I’m often saturated in an environment where I would always end up doing some sort of CAD -- be it working on photoreactors or making a fighter jet that has practically no reason to exist. Nevertheless, a side quirk from this was that I got pretty good (and fast) at visualizing designs, a trait that got me further interested in the world of engineering.

I love my 3D printers!

From receiving my first 3D FDM machine back in my freshman year of high school to managing a 12-printer Prusa/Bambu farm at my current job, 3D printing has always been a cornerstone of my engineering journey and my go-to tool for rapid prototyping.

Machines I’ve worked on:

Prusa i3 Mk3s

Artillery Sidewinder X1

Bambu X1 Carbon

Bambu A1

Bambu P1s

Markforged Oynx One

Creality Ender 3 Pro/S

Creality Ender 5

Prusa SL1

Voron 2.4

Ultimaker S3

Materials I’ve worked with:

PLA

Nylon

CF Composite Nylon

PETG

RCF/PLA

TPU (all durometers)

ABS

PC

I am horrifyingly addicted to CAD.

In 2022, I got my first professional CAD certification as a PTC Onshape Associate.

In some way, it’s some sort of freedom for my brain — I wanted to see how creative my imagination can get when I didn’t have to worry about the constraints of the real world — yet . As a result, many of my creations here didn't stem from a pre-existing need. They were about exploration and the joy of creation.

Current Project(s).

Longboard LED Signaling System

Living and working in a college campus means that there will be pedestrians, cars, scooters and inline skate/longboarders everywhere. As a longboarder, I understand how much of a menace we are in society when it comes to right-of-way intersections and aggressive lane-changes down campustown.

Unfortunately, the only way for us to signal to other people that we’re changing directions or turning is to wave frantically in hopes that our arms can catch the attention of oncoming traffic.

This easy-install signaling device that I am working on will seamlessly attach to longboard trucks and automatically notify others of the rider’s turns, stops, and emergencies — hopefully giving drivers a helping hand in rider awareness.

2025 December

Expected Finish Date

Condor STOVL sUAS

Working on drones at work made me realize throwing things into the air are really cool.

Unfortunately, it’s pretty hard to get something to stay in the air for long. As a result, I’m challenging myself to design a catapult-launched flying-wing STOVL that will be able to loiter for long periods of time and be able to vertically land itself.

This is a personal project to educate myself on aerospace fundamentals and step into the hobby of RC flying.

2025 December

Expected Finish Date